From the National Highway Institute course Underwater Bridge Repair, Rehabilitation, and Countermeasures.

Existing bridge foundations may require modification to support added loads or to develop resistance to anticipated scour conditions. This work has traditionally been executed inside of dewatered cofferdams. However, use of underwater construction techniques may allow this work to be completed without cofferdam installation. Foundation modifications most often include installation of new piles, and extension of the pile cap and pier shaft.

Pile Installation

Driven piles, drilled shafts, or micropiles can be used to increase foundation capacity. Installation of driven piles or casing for drilled shafts may not be feasible due to limited headroom under the bridge. Micropiles are placed in sections and readily installed in low headroom conditions.

If the foundations to be modified are already pile supported, there may not be room to add additional driven piles or drilled shafts within the existing pile group. Piles can be added outside the existing cap and the cap extended; however, this will increase cap bending stresses and may require extensive cap strengthening. While such strengthening could be performed under water, use of cofferdam methods is generally preferable.

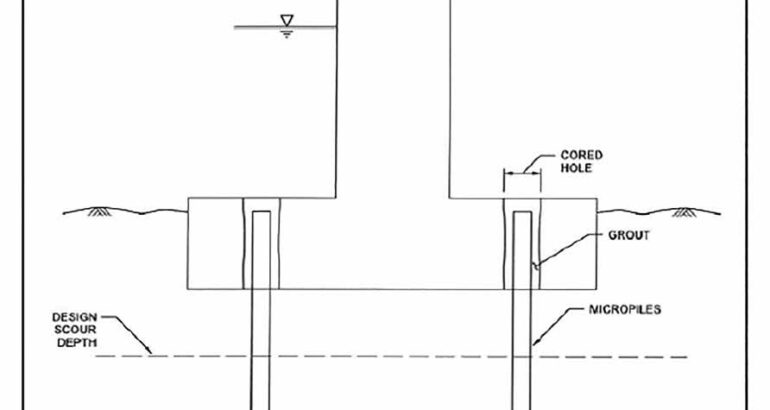

For spread footings, holes can be cored through the footing and piles driven, drilled, or pushed through the holes. Figure 7-16 illustrates the use of piles— micropiles are shown—to extend foundation support into material below the design scour depths. After pile installation, the opening in the footing is filled with concrete or grout. Shear studs and local reinforcing may be needed to properly transfer the pile loads to the footing. Micropiles are well suited to foundation strengthening or modification projects. Advantages of micropiles include their small diameter, ability to be installed in low headroom conditions, high load capability, and installation procedures that do not create significant vibrations to affect the existing structure. Micropiles can be installed as batter piles as well as vertically.

Footing or Pile Cap Extensions

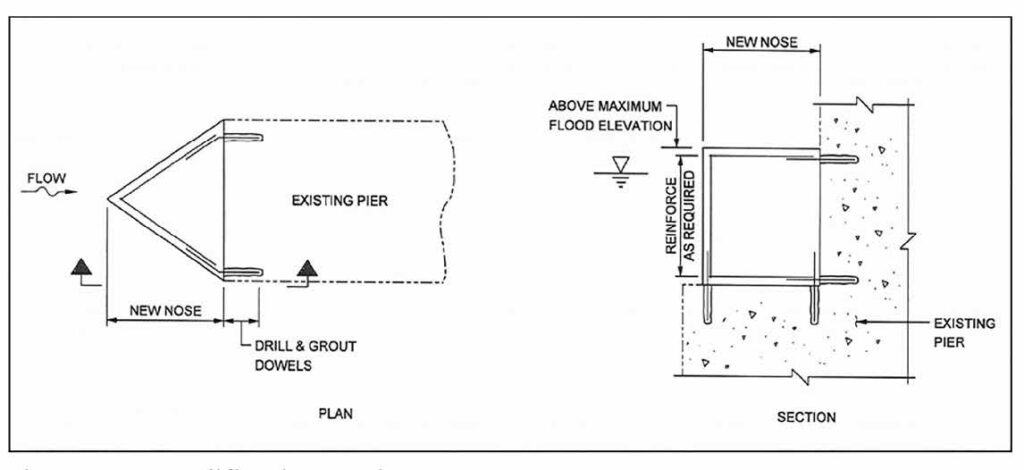

Constructing footing or pile cap extensions underwater is completed in a similar fashion to above water construction. Figure 7-17 illustrates a castin- place modification to a pier nose to reduce flow resistance and scour depth. Drilled and grouted reinforcing steel is placed to secure the old and new construction. Either rigid panel forms or stiffened fabric forms, which would remain in place, can be used to form the extension. Reinforcing steel is assembled above water and set in the maximum size sections that can be handled. Since silts and other deleterious materials can collect on the reinforcing, concrete placement should commence immediately after the reinforcing is set. Dowels may require presetting prior to primary reinforcing placement. Concrete can be placed by pumping or tremie.

Pumping or an inclined tremie are preferable unless the extension is quite thick. Concrete must be flowable and preferably self leveling as vibration is not possible unless the forms extend above water and are well sealed to allow dewatering. To account for the accumulation of laitenance atop the concrete, it is prudent to allow for several inches of “waste” concrete when sizing the footing thickness.

Republished from Marine Construction Magazine Issue V, 2022