Dynamic Load Monitoring (DLM), of Southampton, UK, has provided a custom data logger and subsea measuring technology for use in a new tank where cable protection systems are tested.

Darlington, U.K.-based Subsea Innovation Limited, a designer of innovative subsea and offshore equipment, will primarily use the equipment for testing and verifying their in-house designed subsea equipment such as pipeline repair systems (clamps and connectors), hang-off systems, and other bespoke subsea and offshore equipment.

It will also be used for internal testing for Subsea Innovation’s purpose-designed and built submerged wear test rig. The company also maintains and manufactures deck equipment for cable lay vessels. This is the second major order that DLM has delivered to the company recently, having provided two bespoke monitoring systems that were installed on subsea bend stiffeners at an offshore wind farm. However, DLM is increasingly responding to demand for bespoke and standard solutions from similar maritime technology and marine electronics companies.

Martin Halford, managing director at DLM, said: “We’re putting together systems like this with increasing regularity—incorporating load cells with other instrumentation and sensors. However, no two such jobs are the same. We start with the client’s problem, review what off-the-shelf instrumentation and sensors are available, and then customize the final package accordingly based on the environment—subsea or otherwise—and demands of the application.”

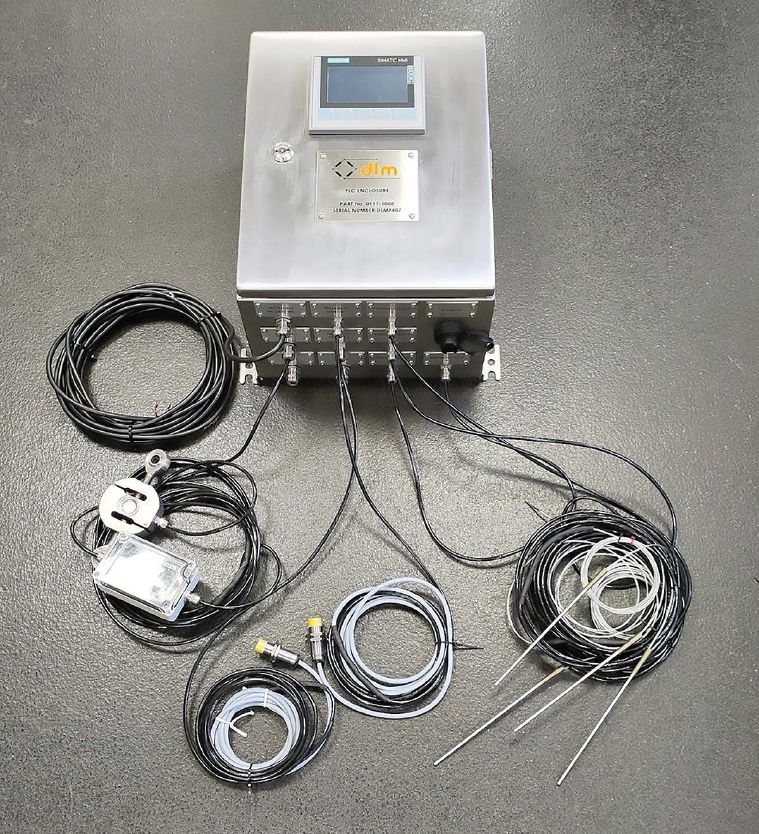

In this instance, a custom data logger takes inputs from several sensors, initially feeding back information on load, rotation, and temperature. More sensors can be added to an expandable system should the need arise in the future. A stainless steel enclosure is mounted in Subsea Innovation’s workshop next to the test tank, which remains in construction. Within the enclosure, the logged data is collated and logged again as a package in a Programmable Logic Controller (PLC) on a memory card.

An Ethernet port, meanwhile, enables the user to plug in a PC to download the data periodically. Halford explained: “You can get a remote view on a web browser of the HMI [human-machine interface] screen to see both live values from the sensors and also download the data logs.”

Integral to the system will be an S-cell load cell from DLM’s standard range, which will be submerged in the tank at a depth of approx. 1m. The load cell is 250kg capacity and will measure in tension and compression. This is the lowest available capacity of a standard range than reaches up to 20t capacity and boasts welded covers, stainless steel construction, sealing to IP68, and high accuracy. It is suitable for use on test stands, to take measurements during certification, and in vessel and tank weighing applications, in addition to retrofit in original equipment manufacturer (OEM) technologies and machinery.

Other standard equipment in this order includes proximity and other sensors, and thermocouples, used for measuring temperature.

Dynamic Load Monitoring’s (DLM) S-cell load cell was an integral component of a custom data logging and subsea measuring system recently installed in a tank where cable protection systems are tested. However, the company frequently modifies and upgrades the product for use in a range of industrial applications.

The S-cell load cell, which was first put to market 10 years ago, is named after its S-shape. It is suited for use in any lifting or renewable energy application where there is a need to measure both tension and compression. Wind industry professionals especially note the product’s accuracy and ability to measure both forces.

DLM recently adapted a model for Vestas to fit a wireless transmitter so it could be paired with a TW-3.0-T display. This load cell and handheld display were used for weighing wind turbine blades. Accuracy is critical as once the blades are weighed, they are classified as light, medium, and heavy for use on each turbine. Once the total weight of the blade is determined, the manufacturer can calculate how much ballast is applied to each blade to create the sets of three to make up a turbine. One rotation of a turbine (three blades) can power a typical home for up to 29 hours. DLM has also made a subsea version with integral 4-20mA Amplifier and subsea connectors.

DLM’s renewables portfolio stretches beyond the S-cell load cell and TW-3.0-T display, with it is now being the manufacturer’s biggest marketplace. Its telemetry shackle load cells, for example, measure the tension on cable pull-ins when connecting power cables to the turbines after they have been installed. Saddleback monitors on the deck of the cable lay vessel, meanwhile, measure the line tension of the cable being laid.

Martin Halford, managing director at DLM, said: “We are busier than we have ever been. It’s interesting that even though we don’t manufacture the S-cell load cell, but we have become renowned for completing modifications and upgrades to enhance safety and productivity in force measurement at the point of use, especially in renewables applications. Often, custom projects incorporate a modified S-cell as part of the package.”

For more information, visit www.dlm-uk.com

Republished from Marine Construction Magazine Issue V, 2022