In 2017, the Australian government initiated the Onslow Marine Support Base (OMSB) Channel Dredging Project, a multi-million-dollar effort to expand the wharf and harbor in and around Beadon Creek. The project includes the construction of a 55-meter-wide shipping channel and deep-water port, and an upgrade of the existing breakwater. Harbor work requires the dredging and reclamation of nearly one million cubic metres of sediment on the seafloor.

OMSB selected Maritime Constructions Pty Ltd, a family-owned South Australian company that specialises in marine infrastructure solutions, to complete the dredging project.

Sikko Krol, manager of dredging & port development at Maritime Constructions and project manager for the OMSB Channel Dredging project, said, “Marine dredging is always a challenge because we can’t see the seabed surface. Added to this, the site is very remote. We needed tools, technologies and a welltrained team to manage the systems and data flow with accuracy and reliability.”

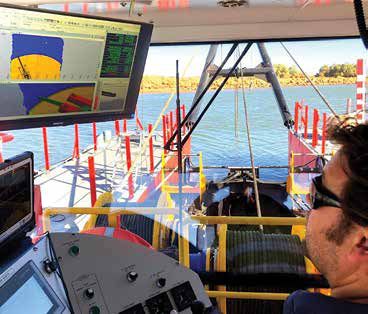

Marine Constructions used the Damen Cutter Suction Dredger 500 “Pilbara Sawfish” (Damen CSD 500) from the Netherlands to complete the dredging work. The CSD 500 is a modular dredge system that includes a spud carriage pontoon to enlarge the swing width, as well as a number of dredging pumps. By default, the CSD machine comes with a navigation system, though Maritime Constructions opted for an alternative dredge monitoring system.

In June 2018, Maritime Constructions looked to UPG (Ultimate Positioning Group) in Adelaide, a Trimble distributor for the “latest and best” in dredge management and navigation. Maritime Constructions has had a relationship with UPG since the late 1990s. In fact, Dene Oehme, current Sales and Technical Consultant with UPG, worked with Maritime Constructions through 2012, where he handled seafloor mapping and managed dredge software and navigation systems.

Oehme explained, “Crews need to dredge to the design channel shape, and the primary challenge is accuracy. If they under-dredge, they have to return and dredge to depth. If they over-dredge, they do not get paid.”

After discussion, UPG and Maritime Constructions settled on a precision 3D guided solution that, at the time, had not been installed on any Australian dredge project, instead of more conventional dredge, survey and re-dredge methods.

The dredger is equipped with Trimble Marine Construction (TMC) software, Trimble MPS865 GNSS Marine Heading receiver, the Trimble Cutter Suction Dredge CAN based sensor kit as well as the linear sensor for spud position data. The contractor also installed an RTK base station, which includes a Trimble SPS855 with multiple GNSS constellations, Trimble TDL450H base radio and Trimble Zephyr 3 base antenna. Surveyors use the Trimble TSC7, Trimble SPS986 GNSS rover and Sonarmite BTX single beam hydrographic survey system.

“The Trimble TMC-enabled solution allows crews to dredge to the engineering design with little or no rework. It also provides the team with the necessary data for daily progress reports and volumes dredged,” said Oehme.

Ease of Operations

Once the dredger was delivered to Australia, Oehme met the Maritime Constructions crew on-site to install, commission and calibrate the Trimble Dredge Management System.

“I trained the dredge crew in the operation of the TMC software and their new surveyor on basic hydrographic surveying techniques as it applies to dredge support,” said Oehme. “Having worked in this exact role at Maritime Constructions for eight years, I knew exactly what they expected, and this allowed me to give specific instructions to their surveyor on the ‘Maritime Constructions way’ of doing things and what they would expect of him.”

3D Precision Dredging Solution

- On the Dredge:

- Trimble Marine Construction software – TMC

- Trimble MPS865 GNSS Marine Heading receiver

- Trimble Cutter Suction Dredge CAN based Sensor Kit

- Linear sensor for “spud” position data

- RTK Base Station:

- Trimble SPS855 with all GNSS constellations

- Trimble TDL450H base radio

- Trimble Zephyr 3 Base antenna

- Surveying:

- Trimble TSC7

- Trimble SPS986 GNSS rover

- Sonarmite BTX single beam Hydrographic Survey system.

The on-site training gave the crews the knowledge to do their system checks and calibrations when required and to extract the daily log and volume data to satisfy both the client’s as well as internal reporting requirements. Besides the dredging work, the precision 3D guidance data is also used for daily progress reports.

Maritime Constructions has completed the dredging and reclamation of nearly one million cubic metres of sediment on the harbour seafloor, with impressive results.

“The Trimble Marine Construction system was essential for efficient channel dredging in this remote part of Australia,” said Krol.