ESC Group continues to achieve significant milestones as it goes beyond 34 years since its first sheet pile was driven at Magnetic Island, Australia in 1986.

Then expansion into Asia in 1991 (firstly Singapore then Malaysia and onto China and more) and set up in the Middle East in 2004. ESC arrived in the USA in 2012.

Now located in twenty (20) countries and counting, ESC has so far established manufacturing and engineering offices in different regions primarily in Asia, the Middle East and North America. This growth through project awards and market footprint spearheaded its recognition and popularity in the global market helping it become one of the foremost trusted products and service providers with delivery of significant projects all over the world.

ESC, over the years, has evolved into an internationally certified organization with full capacity in Engineering and Design, Project Management, Research and Development, Manufacturing, Supply, and Construction.

Heading up operations in the USA is ESC Steel LLC which is an integral part of the Group and now has locations in both North Carolina and Texas. The activities for the entire Continents of North and South America are coordinated from these offices along with those in Mexico and Brazil.

From its humble beginnings as a manufacturer-supplier of steel sheet piles, ESC has successfully incorporated Engineering Support and Design to its discipline as a systematic approach to Foundation Solutions, Marine Piling, Marine Equipment, Trench Safety, Corrosion Control, and diversified Structural Steel Fabrication.

ESC’s traditional offerings cover:

ESC’s Marine & Foundation Piling product range consists Steel Sheet Pile and Vinyl Sheet Pile, H Pile and Pipe Pile Combination Walls, Steel Pipe Piles, Strutting Systems, and Tie-rod Systems.

Over the last 10 years ESC has increased its product offerings based on requests from clients and also as part of our ever growing product development program. The ranges include:

ESC’s Trench Safety range incorporates Trench Shields/Boxes which are a two-sided, high-quality and economical excavation support system that provides a safe working environment in trenches.

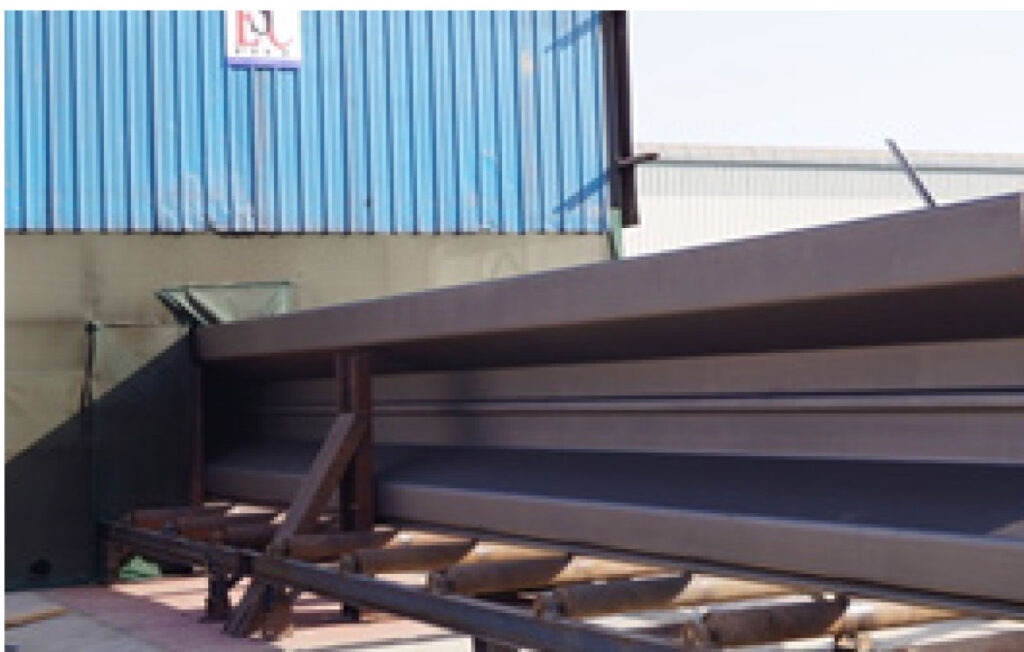

ESC’s Structural Steel Fabrication Division covers up Steel Bridge Structures, Pre-engineered Steel Building / Prefab Steel Buildings, Offshore Steel Structures, Heavy Steel Fabrication, Pressure Vessel, and Material Handling Structures. ESC supplies steel columns, purlins, frames, trestles, beams, trusses, conveyor gantries, mineral processing plants, crusher and screening structures, bridges, walkways, ROM bins, stairs, platforms, handrails, guards, grating, conveyor supports, frames, towers, pipe racks and mechanical support steel.

ESC’s Corrosion Protection Systems provides high quality corrosion protection by means of coatings: Coal Tar Epoxy, Glass Flake Epoxy Coating, Hot Dip Galvanizing, and Duplex Coating System; and Cathodic Protection; or the combination of both.

Further to simply supplying products, ESC takes a different approach to its product ranges which are often tailored to the customers’ requirements. ESC believes that just supplying a product is insufficient and we strive to provide a level of support that is beyond customer expectations. This support ranges from general advice on the Client’s options to full engineering support and design.

ESC Entities are either contractors, engineers and manufacturers or a combination of all three in various parts of the world. ESC Steel in the USA in particular aims big and will be continuing its domestic manufacturing set up and looking at installation aspects of the business with external and internal resources.