JMS Naval Architects has completed the concept through contract-level design of a floating dry dock for an undisclosed client.

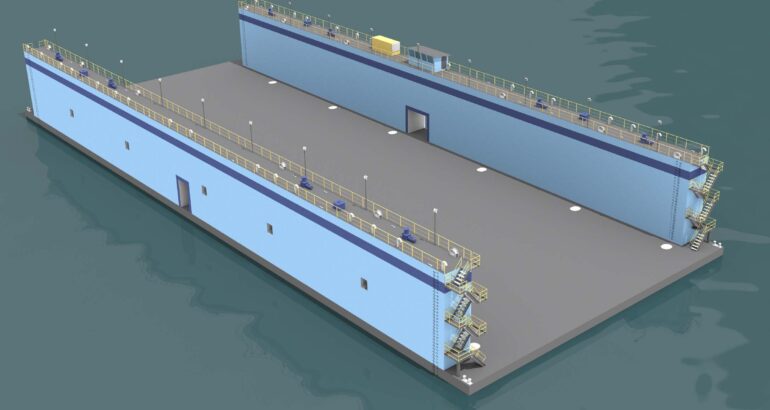

The dry dock is a single section dry dock with the pontoon and wing walls permanently joined. The dry dock is 288 feet long overall, 120 feet wide with a pontoon depth of 9 feet, and a wing wall height of 30 feet above the pontoon deck. The dry dock has 6 pairs of port and starboard ballast tanks.

The dry dock is capable of docking vessels up to 4,500 LT and 20 feet in draft. The dock can be submerged to a draft of 34 feet with 5 foot keel blocks, but JMS designed the dry dock to operate in water as shallow as 25 feet, with 11 feet of water over the blocks.

A 12 foot wide tunnel through the starboard side wing wall allows forklift access, and a 6 foot wide tunnel is fit in the port side wing wall. A control house is located amidships on the starboard side top deck. The port and starboard top deck will be accessible via a stair tower installed on the aft end of each wing wall as well as a vertical ladder installed on the forward ends of each wing wall.

The top deck and safety deck are equipped to operate the dry dock and position the docked vessel. Four capstans are located on each side of the top deck. Valve actuators and valve handwheels are located on the safety deck to operate the ballasting valves.

The ballast system consists of an electric submersible pump per ballast tank for dewatering. The pumps are rated for a flow rate of 2,500 GPM at a total head of 20 ft. Discharge piping is hard piped and discharges above the pontoon deck. The ballast tanks are flooded by hydrostatic pressure through 12-inch gate valves mounted on the side shell. Valves are operated via actuators on the safety deck via reach rods. Redundant deballasting is provided by cross over valves between adjacent tanks in the pontoon. The total expected time to ballast and deballast is 3 hours.

The dock will be moored using mooring lines. Double bitts, 12-inch single bitts, and 24-inch kevels are located on the Pontoon Deck, Safety Deck and Top Deck. The bitts on the Safety Deck are recessed within side shell pockets. The kevels and 8 motor-operated capstans are located on the Top Deck to assist in vessel handling during the docking evolution.

The electrical power generating plant includes one enclosed diesel generator with a continuous rating of 350 kW at 480 V, 60 Hz installed on the starboard side top deck. The generator is skid mounted with a subbase fuel tank and a weatherproof sound-attenuating housing.

Shore power is also supplied via a permanent connection to the main electrical panel to permit operation of the dock alongside a pier without the generator. A 400 A, 480 V shore power feed provides power for the pumps, capstans, and welders, and 208/120 V distribution is provided via step down transformer for lighting, controls and other service loads. Docked vessel shore power can be supplied for 480 V, 100 A and 208 V, 50 A. Lighting is provided on the top deck, safety deck, and stair tower for safe access, and floodlights are provided to illuminate the dock floor when working at night.

JMS developed the complete engineering and design package, including all detail structural design, tankage, and outfitting design. Systems design included the ballast system, seachest arrangement, equipment specification, pump and discharge piping systems. JMS also designed the power system including generator arrangement, fuel tank arrangement, and electrical and piping systems one-lines. The dry dock has been designed in accordance with ABS Rules for Building and Classing Steel Floating Dry Docks 2020. The design will not be reviewed by Class or built under survey by Class.