By Fred H. Kulhawy and Anwar HiranyFrom the Encyclopedia of Physical Science and Technology (Third Edition)

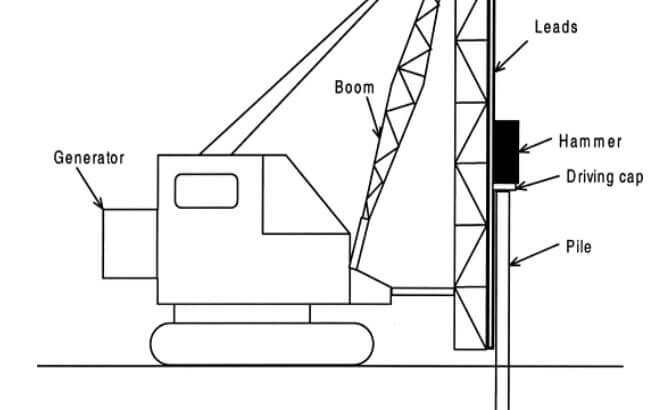

Typical pile-driving equipment includes a crawler-mounted crane with a boom, leads, hammer, driving caps, and other accessories all connected to form a unit. This unit must be strong enough to guide and drive each pile accurately to its final position and withstand safely all loads imposed during the pile driving process.

Pile hammers can be grouped under impact (drop hammer, steam or air hammer, diesel hammer) or vibratory types. Drop hammers are the simplest and oldest type of impact hammers. They consist of a guide weight or ram that is lifted up to a required height by a hoist line and then released. The drop hammer is best suited for small projects that require relatively low capacity and employ lightweight timber or steel piles. Other types of impact hammers include the steam or air hammer, in which steam or compressed air pressure is used to raise the ram. The ram falls freely and strikes the drive cap when the pressure is released automatically. These hammers can be used for a variety of different pile–soil combinations, but they are best suited for timber and H-piles in sand.

Diesel hammers are self-contained, lightweight, economical, and easy to service. Initially, the ram is raised by mechanical means, and the fuel is injected into the cylinder while the ram drops. When the ram strikes the anvil, the fuel is ignited, explodes, and forces the anvil down against the pile and the ram upward. The sequence repeats itself automatically, and the pile is driven into the ground by the ram impact and the explosion of the fuel. Diesel hammers are best suited for hard driving conditions and do not work well in soft soil because of the driving resistance required for compression and ignition of the fuel.

Vibratory hammers utilize eccentric weights that are rotated with the help of electric or hydraulic motors to produce vertical vibrations. The vibrations reduce the frictional soil resistance along the sides of the pile and also loosen the soil at the tip. This type of hammer is best suited for steel piles in sand. Clay soils dampen the vibrations of the hammer and therefore reduce pile penetration. These hammers are not effective in penetrating soils with large obstacles and boulders and are not suitable for concrete or timber piles.