Dynamic Load Monitoring (UK) Ltd. (DLM), of Southampton, U.K. continues to reinvest in its hire (or “rental,” in American English) fleet, as demand grows for short- and mid-term use of products such as its running line monitors (RLMs).

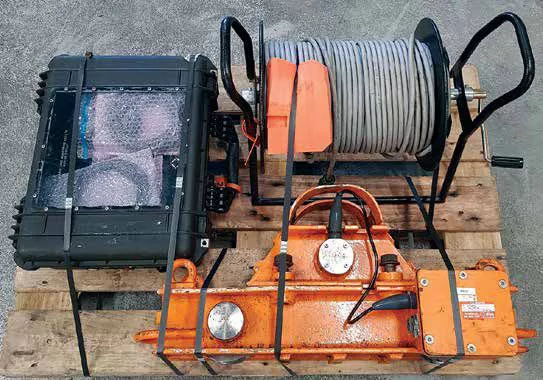

DLM’s standard range of RLMs (15-, 60- and 200-tonne capacity) are designed specifically for harsh marine-type environments. They are typically used in cable laying, towing, mooring and other winch operations to measure and record line tension, pay-out, and speed. Available in cabled or wireless configurations, they can be integrated into existing vessel systems, or supplied as stand-alone systems with individual or multi-input HMI displays, with touch screen and data logging capabilities.

DLM also has available for rental telemetry or cabled tensile links, handheld displays, compressive load cells, shackle load cells, saddleback monitors, cable counters, and an extensive range of grapnels.

Jamie Woodcock, business development manager at DLM, said, “Our rental department is increasing all the time and we are constantly investing in the fleet to meet the ever growing technical and specialist demands of our customers, as well as being able to service multiple projects with identical requirements at the same time. We rent to multiple industries, predominantly subsea cable laying, lifting, rigging, testing and inspection. This is what makes us different: we have various products for a range of industries.”

Woodcock explained that most rentals are for multiple items of equipment, which might be several tensile links, shackles, or compressive load cells for the lifting and rigging sector, or multiple RLMs & displays for an offshore project. This requires DLM to have multiple units of the same equipment and working ranges, available in their rental fleet. The marine industry also regularly rents multiple items, to be used in conjunction with each other, such as RLMs with a saddleback and a grapnel train—part of DLM’s new pre-lay grapnel run (PLGR) deck spread. With rentals for the marine/ offshore industry often lasting up to 120 days at a time, the need for a large rental inventory is illustrated further. One rental even spanned an entire year. In contrast, rentals for lifting, rigging, test and inspection applications can be as short as a single day. However, with only 12 hours notice for mobilization, sometimes the equipment needs to be ready for immediate dispatch, which is a strength of DLMs.

A recent rental case study included mobilization of a 60-tonne capacity RLM, accompanied with a customized 34mm wire rope for Dutch distributor CIV Offshore & Shipping. Adrian Farwell, DLMs marine sales manager said the order was notable by a short lead time. The equipment was prepared and shipped to the Netherlands on a designated vehicle to urgently meet a customer, before it was transported by vessel to the Far East for a PLGR operation at an offshore wind farm. The rental duration is expected to be circa six months, or longer. Other recent rental projects included tensile links and shackle load cells for lifting water bags for load tests and weighing / calculating the total weight and center of gravity of various large structures.

Woodcock added: “The customer can have up to date, certified and reliable equipment every time they need it without having the maintenance costs. All equipment is supplied with a valid calibration certificate for the duration of the rental, and it can be mobilized at short notice with all the functionality the end user requires. As a lot of offshore projects last from 30 to 90 days, the benefits of not owning the equipment can help to reduce CapEx spend and overall project cost. Short-term rental will be cheaper than purchase. For the lifting industry customers can also rent our proof test software for the duration of the rental which allows the operator to generate a PDF certificate to evidence the test being completed.”

For more information, please visit www.dlm-ik.com.

Republished from Marine Construction Magazine Issue IV, 2021