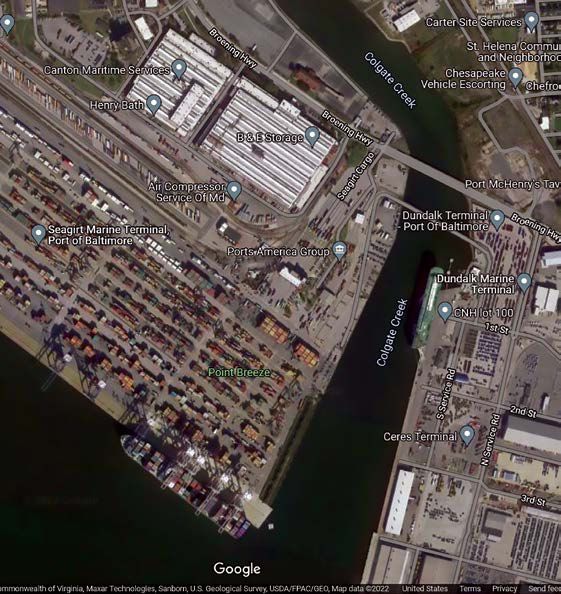

Baltimore, Md., U.S.A

BACKGROUND

The Port of Baltimore, founded in 1706, is the seventh largest container port on the United States’ East Coast. Bert 3 is one of four that are served by a 50-foot channel on the Patapsco River, leading to the Chesapeake Bay and into the Atlantic Ocean. Dundalk Marine Terminal (DMT) is the largest and most versatile general cargo facility at the Port of Baltimore. DMT has 13 berths, five container cranes and direct rail access, and dates back to the 1930s. DMT handles cars and heavy farm and construction machinery, and the Port of Baltimore is ranked first among all U.S. ports in both categories.

CHALLENGE

The Port, and in turn, the Dundalk Marine Terminal, is located in one of the country’s strongest markets, and is a gateway for the import/export markets to and from rural areas, including heavy farming equipment. The Berth 3 project is designed to strengthen and reinforce the Dundalk Marine Terminal berths to better accommodate the heavy machinery that is handled there. In addition, harsh marine conditions and age made rehabilitation of several berths a requirement before they became unstable and unusable.

SOLUTION

Cianbro Corporation, of Pittsfield, Maine, won the contract for the work on Berth 3. The contract included demolition and removal of a timber pile-supported wharf and the construction of approximately 48,000 square feet of a new marginal wharf. Additional work in the contract includes the reconstruction of the bulkhead with a new combi-wall system and an H-pile supported relieving platform. Cianbro is also responsible for the dredging of the site to allow for Panamax-sized vessels. The engineer of record, Moffatt & Nichol, has a long-standing relationship with Nucor Skyline. They trusted Nucor Skyline to provide the highest quality steel piling products for the job.

The combi-wall bulkhead consists of Nucor Skyline’s W 33×241-wide flange beams and NZ 26 sheet piles. Other work on Berth 3 includes H-piles and NZ 38 sheet piles, also supplied by Nucor Skyline. All of the products were coated with coal tar epoxy to extend their life in the caustic marine environment.

Work on Berth 3 has recently begun and the driving of the combi-wall and other steel products will be completed soon. The Port of Baltimore expects Berth 3 to be operational by the end of 2021.

PROJECT PARTNERS

Owner: Port of Baltimore, Baltimore, Md.

General Contractor: Cianbro Corporation, Pittsfield, Me.

Engineer: Moffatt & Nichol – New York, N.Y.

PRODUCT

Wide Flange Beams: W 33×241 (875 tons)

Sheet Pile: NZ 26 sheet pile (665 tons)

NZ 38 sheet pile (78 tons)

H-pile: HP 14×89, 12×53 (1,335 tons)

PROJECT TIME FRAME

January 2021 and continuing

Republished from Marine Construction Magazine Issue V, 2022